FIP Journal - Volume 10

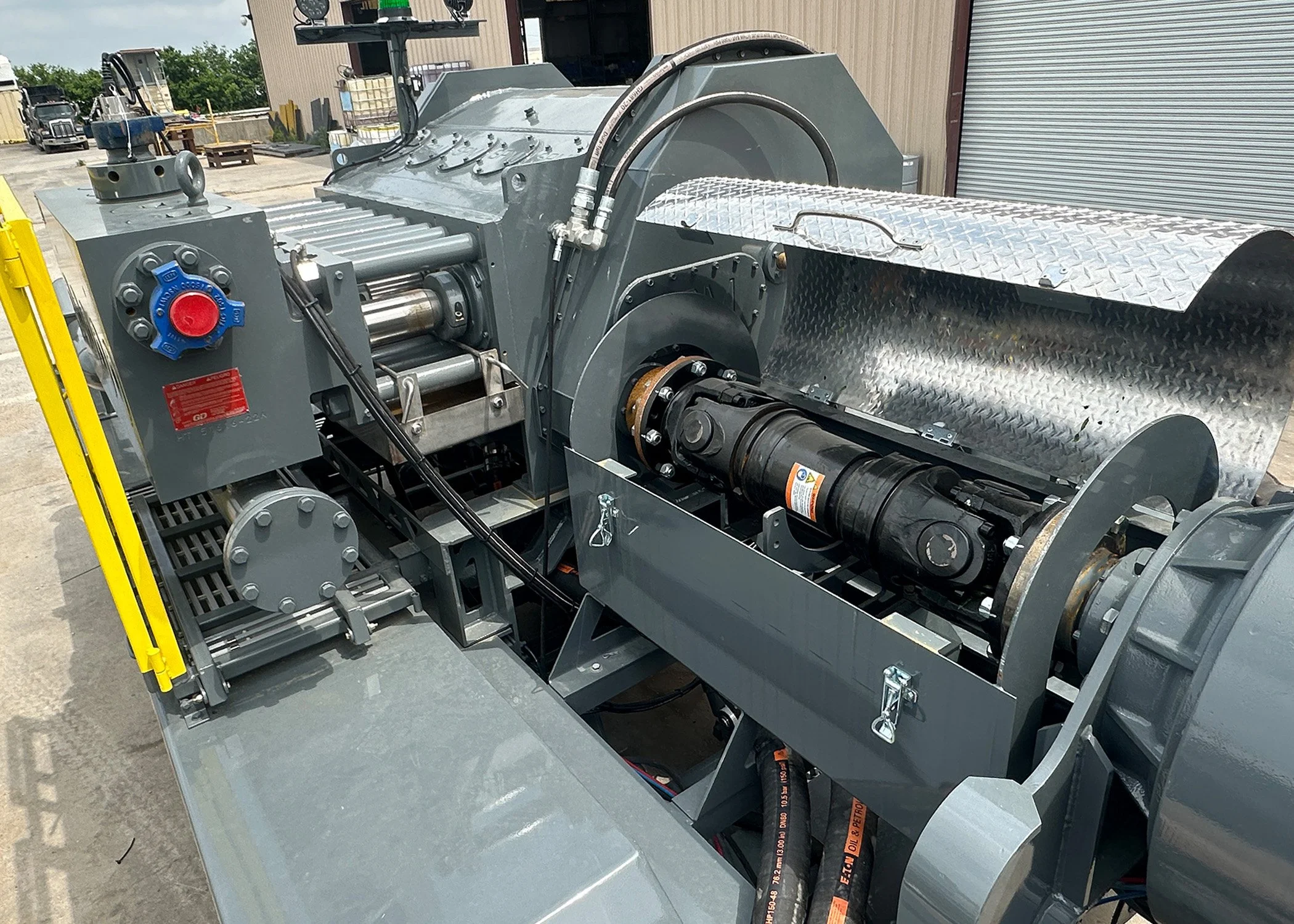

Power End & Driveline Assembly

Stick’s Box

Power Frame Stresses

Conventional power frames are a very stressed structure. On one hand, the pinion shaft is riding in the frame, supported on each end by roller bearings. These continually receive a supply of oil to carry the heat away and prevent metal-to-metal contact. Not a big deal when it's just one shaft turning; unfortunately, it must act as a ratio and force the crankshaft to rotate through a set of gears. This puts a lot of outward force on the power frame. The pinion is being driven away from the crankshaft and downward under tremendous force while continuing to rotate the crankshaft.

Now, the crankshaft is in a similar situation. It's being driven in rotation by the pinion and forced away from the pinion by two extreme forces: the force that the plungers are exerting and the forces the pinion exerts on the bull gears. The crank wants to go up and away from the pinion. The only item, besides a robust frame, keeping all these forces from winning is a set of roller bearings continually lubricated by oil, which hopefully isn't aerated, dirty, and hot. If maintained and the system isn't violent, the unit will last for a long time. Unfortunately, we know that isn't always the case. Stress is always just around the corner.

Incidents that continually push and force bearing bores out of round are always around the corner. Normally, if you are pounding the rod bearing, you are also pounding the mains. The force is transmitted through it all. The only hope you've got is a superior pressurized lubrication system. Valves going bad, cavitation, screen off, issues encountered during operation all get transmitted back into the power frame and its components, all causing damage that shows itself later down the line. Keep it clean, cool, and absolutely pressurized.