Volume 8 Maintenance Bulletin 2024

Power End Lubrication

Stick’s Box

On the subject of Power End lubrication, I want to touch on bearing shells. Although there are a few different styles of bearings in a Power Frame and surfaces that need lubrication, I'm just going to focus on bearing shells of the rods, which are typically the most worn items in a Power End.

A shell bearing with adequate oil pressure and sufficient clean oil flow will last indefinitely. What makes them fail? Uncommon failures happen from mixed oils or dilution. Normally, failures arise from the lack of proper filtration introducing particles into the oil system, leading to premature wear on the lubricated side of the bearing. This will also be reflected on the surface of the crank.

Another cause is heat acting upon the oil, rendering it incapable of carrying any load. The force exerted on the rod compels the bearing surface into the rod journal.

Aerated fluid is the silent killer, passing virtually undetected due to the time lapse between failure and getting the unit back to the facility for inspection.

The other silent killer is scuffing over time when the unit is engaged into gear, and the treating line has treating pressure on it. Normally, a gear range is selected, the driveline is in a stalled state, and then RPM is given, initiating the rotation of the driveline, and overcoming the force needed to turn the power end. It is at this point that scuffing typically occurs. Compounded with every job over time, premature wear is imminent. This can be observed at bearing inspection intervals set by the duty cycle of the unit.

I have seen start-in pressures as low as 25 psi at operating oil temp. The wedge of oil protecting the bearings at this point is virtually nonexistent. Ensure your systems are sized, and the pressure is set for these conditions. Because rated speed oil pressure is significantly higher than start-in oil pressures, I aim for at least 75 psi at idle when hot.

The filtration on these components doesn't have to be exotic; it just has to maintain a cleanliness level and handle the flow through its usable service life. On a small note, check the bypasses and ratings on the filtration you have; you may be introducing contaminants into the system. I typically don't run bypass filtration, but I've found a significant amount bypassing at startup and during operation. Heston Starkey – Ops Mgr

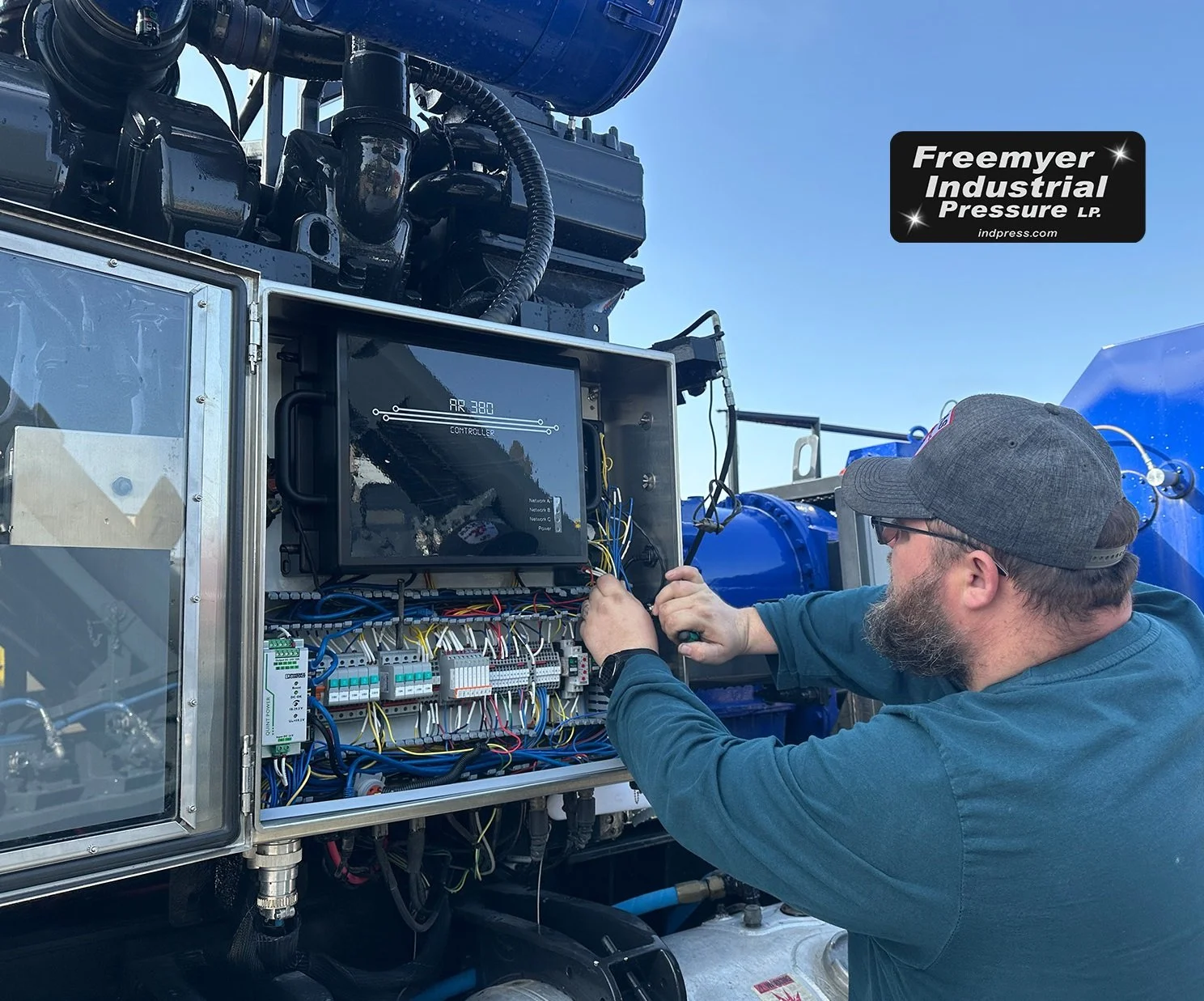

Tony – FIP Lead ET & Trainer

Technology is ever evolving. If you do not stay up to date on the latest advances, you get left behind. That is what we strive to achieve here at Freemyer Industrial Pressure. Keeping up with the newest technology is of great importance and allows us to not only stay ahead of the game but also to put out the best equipment in the industry. Another very important aspect of Electronics, is ease of use. Operators prefer to run equipment that has easy to use, and understand, controls. The tricky part is to build controls that are very easy to operate without losing functionality.

The controls we build are a perfect balance between being user-friendly and functionality. This not only pertains to the software side, but also the hardware side. A technician needing to troubleshoot an issue does not want to open the control of the controls box and see what looks like a spilled pot of spaghetti. That is why the control boxes built here are neat and orderly, with wire labels on every wire and easy to access components. I am constantly making changes to limit the number of fail points and eliminate any extra or redundant components. The last item you should know about is perhaps the most exciting. With the ability to connect and run the unit wirelessly, you will no longer have to drag heavy cable through dirt and mud every time you rig up or down. This also allows your customers to connect and monitor the important data of a job while it is being pumped.

Our number one priority is YOU, the customer. We have the flexibility in our controls to meet your every need. We build each control system as if we were going to be running it ourselves. “Every job is a self-portrait of the person who did it. Autograph your work with excellence.” - Tony