June 2023 Information Journal

Upgrading Existing Assets

Upgrading the major components of existing assets to increase performance is ideal, as it not only lowers the upfront costs but also decreases completion times. Although major component deliveries, specifically the engine and transmission powertrain, are starting to improve, upgrading existing assets has its advantages. Other advantages include the ability to utilize and restore some existing components such as the trailer chassis, engine, transmission, and control system, typically with new cables and sensors. Additionally, there are benefits reflected in the financial statements and balance sheet, as the older legacy assets are either in or nearing scheduled depreciation. Lowering the initial cost of restoration compared to new build costs helps facilitate a quicker return on investment, enabling the equipment to be deployed faster and generate revenue with its revitalized performance.

Some clients prefer to undertake their equipment readiness projects in batches. For example, a recent project involved several fracturing units that were originally configured with a Horizontal Cooling Package, MTU 12V4000 Engine with CAT Transmission, equipped with a 2250 HP Triplex Pump Assembly. The upgrades for this project included a new Cube Style Cooling Package, servicing of the Engine and Transmission, installation of a new 3000 HP Quintuplex Pump Assembly. Also, an upgrade to the Fan Drive System that eliminated the existing potentially problematic driveline assembly by installing a direct-drive Hydraulic Fan Pump System.

Whether you are considering a fleet of equipment or upgrading single units at a time, please contact us to discuss the level of upgrade, restoration, and the approach to optimize your equipment. FIP is focused on providing solutions to help reduce your initial cost of ownership and facilitate a prompter return on your investment. - Greg Leos (VP)

Stick’s Box

There's no question in pumping applications: which component fails the most? The actual pump. It is the part of the system that converts all the horsepower and torque into the force required to move the reluctant proppant or slurry through the network of high-pressure piping and directs it into the well and beyond.

This pump, as we call it, is subjected continually to severe levels of abuse, be it on a torsional level due to never maintaining the torsional damper, simply not maintaining fastener torque, a warped or failing unbalanced driveshaft, bad components in the fluid ends—the combinations are endless, right down to the pump base design, which is usually the most rudimentary item on the unit; actually, transmitting bad things into the pump instead of helping to remove them, after all, the torsional damper is only there for so much if there is one.

Most of these failures are blamed on crazy stuff, like, "All the bull gear bolts broke off, they must be a bad batch" or "These connecting rod bolts failed; they must have not been torqued right. Should have used red locking juice." Just imagine the failures coming from or being induced into the pump from elsewhere. You may surprise yourself with what you find. We all know it's hard to rewind beyond a point of failure to see what happened. Often the conclusion drawn is the wrong one, and the system repaired or installed is subject to the same forces that failed the previous. After all, all failures are learning experiences. - Heston Starkey (Ops Manager)

Letter From Len

Help Others Become Successful: Success is not too complicated; you have "to get things done." Do it yourself or ask for help or give help; these are the three ways to get it done.

Obviously, doing everything yourself produces less than getting help or giving help. You can only become successful as your own time and efforts allow. Outstanding success comes through expanding efforts through others. Have you heard the saying "to have a friend, you must be a friend"? This is sort of the concept.

Helping others be successful, and then they help you when you need it. It may sound corny, but it sure makes life more enjoyable. A fellow named Clint, whom I worked with early on in my oilfield life, helped me with everything. I did my best to help him back, but I always felt he did more for me. He was so talented at fixing things and so confident at work, and I grew stronger just by associating with him.

In a company, the boss should help those working for him, and all those should help the customer be successful. Just help them. Len Freemyer (President)

QUICK HITS

History:

Phillips Petroleum Company:

Phillips Petroleum Company was founded in Bartlesville, Oklahoma during the early months of World War I. The company grew rapidly, with assets increasing from $3 million to $100 million within a few years. In 1927, they started selling gasoline and eventually established over 10,000 Phillips 66 service stations. Their high-octane aviation fuel played a crucial role in World War II. – AOGHS

First New Mexico Oil Well:

In 1922, New Mexico's first commercial oil well was drilled near Shiprock by the Midwest Refining Company. The Hogback No. 1 well and subsequent wells in the area established the Hogback oilfield as a significant producer in the San Juan Basin. A pipeline to Farmington was completed two years later, allowing oil to be shipped by rail to Salt Lake City for refining.

FIP

Electric Solutions - REDEEM GREEN®

Fracturing

Stimulation

Cementing

Specialty Pumping Units

Electronics & Data Acquisition Solutions

Offshore Solutions

Pumps for CTU Support

Rebuild, Refurbishment, Restoration

After Sales Support

Fire Suppression Systems

Trailer Mounted Fracturing Units

Cooling Package Changed to Cube Style Radiator Assembly

Servicing of Powertrain – Engine & Transmission

Upgraded to 3000 HP Quintuplex Pump Assembly

Power End Lubrication System Upgrade

Hydraulic System Upgrade

New Hose Assemblies Installed

Please contact us to discuss what level of upgrade, restoration, and approach to optimize your equipment.

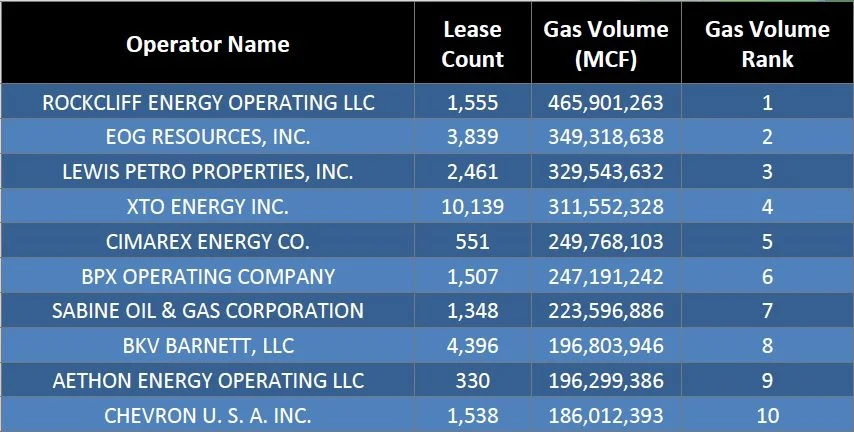

2022 Texas Production Ranks by Operator (Gas)

*Source: Railroad Commission of Texas